Powering Tomorrow with Quality Fabrication

ABOUT US

A.E. Jambukar

Founder

KAJ Engineering, established in 2000, is a leading manufacturer of pressure vessels, heat exchangers, transformer tanks, core frames, distillery equipment, and HVAC systems, proudly aligned with the “Make in India” initiative. With two advanced facilities in Pune Maharashtra and one in Tirupati Andhra Pradesh, our manufacturing operations are equipped with modern automation and managed by highly skilled engineers. We specialize in heavy fabrication works in MS & SS, delivering products such as pressure vessels, tube-type heat exchangers, oil tank separators, filters, chemical and beverage tanks, transformer tanks, and compressor base frames.

At Kaj Engineering Works and Kaj Power Systems Pvt. Ltd., we uphold the highest standards of strength, precision, and quality in every fabrication and weld. Our operations follow AWS, ASME, and ISO 9001:2015 standards, supported by advanced SMAW, GMAW, GTAW, and FCAW welding facilities for MS, CS, and SS materials. We specialize in the fabrication of transformer tanks, core frames, pressure vessels, heat exchangers, and heavy structures.

All welders and WPS/PQR procedures are approved by IEW, ASNT Level III, TÜV, and Lloyd’s, ensuring certified workmanship and consistent weld quality across all projects.

Combining advanced facilities, experienced manpower, and robust quality systems, we are committed to our

VISION

Quality First & Dispatch – Precision, Reliability, Commitment.

MISSION

-

Deliver world-class heavy fabrication solutions

-

Support transformer OEMs, energy equipment & industrial clients

-

Achieve global benchmarks in quality, timeliness & customer trust

OUR SERVICES

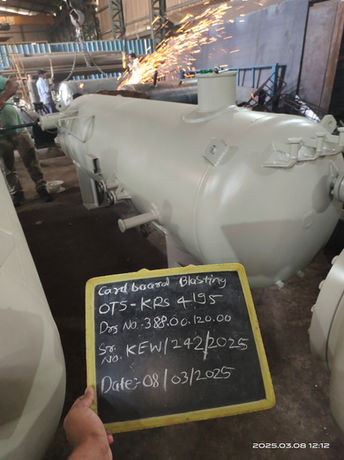

FABRICATION COMPONENT

Transformer Tanks

Core Frames

Yoke clamp

Booster oil tank 37 kw

Air Receiver

Tube Sheet Bundle Assly

Lube Oil Cooler

Inter stage gas cooler D4

OUR PROJECTS

OUR CLIENTS

.png)

INFRASTRUCTURE & FACILITIES

Andhra Pradesh Plant (Tirupati / Naidupeta SEZ)

-

Bay-1: 20 m × 75 m; 10 Ton × 2 cranes; clear height 6.5 m

-

Bay-2: 20 m × 75 m; 7 Ton × 2 cranes; clear height 6.5 m

-

Bay-3: 20 m × 75 m; 5 Ton + 10 Ton + extra 5 Ton; clear height 6.5 m

-

Total Built-up Area: ~4500 m²

Chakan Plant (Kaj Power Systems Pvt. Ltd.)

-

Bay-1: 22 m × 52 m

-

Bay-2: 13 m × 31 m

-

Crane Capacity: 10 Ton EOT Crane

-

Specialization: Transformer Tanks, Core Frames, Headers, Spares , shell and tube type heat exchangers.

-

Total Built-up Area: ~1731 m2

Pune Plant (Talwade, Maharashtra)

-

Shop Size: 20 m × 50 m

-

Cranes: 15 Ton + 5 Ton

-

Clear Height: 9 m

-

Total Built-up Area: ~1000 m²

GET IN TOUCH

Contact Us

Head Office & Manufacturing

KAJ GROUP OF COMPANIES

(Kaj Power Systems Pvt. Ltd. & Kaj Engineering Works)

Head Office & Manufacturing Unit–I : Maharashtra

Kaj Engineering Works, Gat No. 78, Jyotiba Nagar, Talwade, Pune – 411062, Maharashtra, India.

Manufacturing Unit II : Andhra Pradesh

Kaj Engineering Works, Menakur Industrial Area, Naidupeta, Tirupati - 524421 Andhra Pradesh, India.

Manufacturing Unit III : Maharashtra

Kaj Power systems Pvt Ltd.

Gat No. 482, Mahalunge, Chakan, Tal. Khed, Pune – 410501, Maharashtra, India.

Drop us an email at:

You can also contact us at:

+919922945311